Inventory Monitoring and Tracking with RTLS solutions

Wireless inventory tracking system

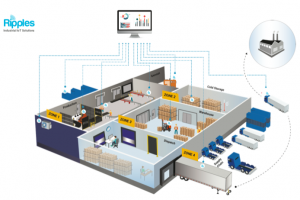

Wireless inventory monitoring and tracking – The deployment of RTLS solutions for warehouses and various other industries is deemed a key factor in driving smart warehouse and facilities management. Often the promise made by the vendor is that by building digital representations of physical assets, indoor assets, inventory tags, and shop floor workflow on which additional insights will be derived from indoor positioning data analytics to drive new information insights and revenue opportunities. Nowadays it’s important to monitor workplace safety using RTLS solutions for inventory tracking

Digital technology & visual representation of the operations.

In a supply chain, RTLS solutions for warehousing inventory tracking by the deployment of inventory tags mean, the operations on the production floor will be depicted by multiple zones of moving inventory to create a digital twin, data needs to be gathered from different operations on the shop floor functions and moving objects effectively mapped in real-time. Without data, the visual representation is only a hollow concept. The question is how to build more of a twin and less of a hollow concept.

This boils down to several factors; some are organizational and operational, while others involve technology and the availability of know-how. The latter, in my view, is one of the biggest hurdles, but it is not independent of the technology or ecosystem of choice. At RipplesIPS, we believe in open-source technology and open API-based democratizing access to machine-generated data to implement digital twins in the warehouse, IoT in yard management, and transport management.

Monitoring workflow & workplace safety

The RTLS solutions for warehouses can also be extended to monitoring worker safety in logistics yards, construction sites, etc. Given an accuracy of 2.5 sq meters, it is possible to ascertain using demand forecasting, the time spent by a group of people to trigger health safety when a worker crosses into a no-go zone. This will help in functions such as facilities management.

RTLS solutions with wireless inventory trackers

This means that the cost structure of the Industry 4.0 solution will be appropriate, and accessible to a larger, global audience. Many of the prevailing RTLS connectivity protocols incur huge expenses in the bill of material by using outdated and proprietary radio HW and or transmission protocols.

Another important deployment aspect for consideration is the installation time and effort to configure your digital twins in transport management and warehousing. This has a direct impact on savings and can offer a large cost component in any industrial deployment of RTLS Inventree in factories, warehouses, and construction industries. Our solutions around Wirepas indoor positioning systems mesh network topology are truly self-organizing and autonomous RTLS solutions for asset tracking systems in warehouses.

Algorithms running in each Bluetooth Low Energy radio decide how best to organize the network, its topology, and the use of the radio spectrum. This eliminates network planning, reduces installation time, and most importantly, the deployment can be a simple part of daily routines by warehouse workers saving a lot of time and effort in installation, implementation, cabling, inspection, and certification.

Call us to learn how to implement facilities management, warehouse inventory tracking, and transport logistics cargo monitoring, RTLS solutions for inventory tracking system in the warehouse.