Advanced Warehouse Monitoring and Tracking with RTLS Technology

Efficient Wireless Asset Inventory Tracking Solutions

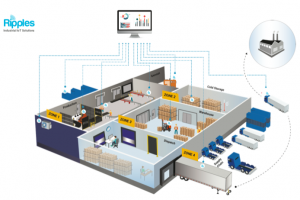

Digital twins warehouse management solutions are a virtual, real-time replica of a physical warehouse or logistics yard and its operations. It uses data from various sources like IoT sensors, automation systems, and warehouse management systems (WMS) to mirror the physical environment, including the layout, people, inventory, equipment, and workflows. This dynamic digital model allows managers to monitor, analyse, and optimise warehouse performance in a safe, virtual environment before implementing changes in the physical space.

Wireless inventory monitoring and tracking using Digital Twins warehouse management – The deployment of RTLS solutions for warehouses and various other industries is deemed a key factor in driving smart warehouse, yard management and facilities management. Often, the promise made by the vendor is that by building digital representations of physical assets, indoor assets, inventory tags, and shop floor management workflow which additional insights will be derived from indoor positioning data analytics to drive new information insights and revenue opportunities. Nowadays, it’s important to monitor workplace safety using RTLS solutions for inventory tracking.

What we offer as part of our Digital Twins warehouse managements

Our warehouse digital twin offers a scalable layout map that depicts in real-time, indoor and outdoor, the position and movement of various asset inventory items with geofencing options. This is applied to stationary and moving objects, demarcating various zones on the shop floor. Our tracking and monitoring solution provides complete visibility across your facility:

Inventory Management

- Total Stock Control: Implement FIFO (First-In, First-Out) and enable accurate, efficient cycle counting and stocktakes.

- Yard & Theft Protection: Quickly locate any pallet in the yard, track all inventory movements, and issue instant theft alerts.

- Planning: Utilise demand forecasting for inventory replenishment and fleet resource allocation.

Workforce Safety and Security

- Personnel Tracking: Track employees, contractors, and visitors with a unified system.

- Lone Worker Safety: Features include fall detection and dedicated Lone Worker monitoring systems.

- Access Control: Define permitted zone demarcations (geo-fencing) to restrict and alert on personnel movement.

Fleet, Cargo, and Asset Integrity

- Yard Logistics: Monitor the real-time movement of trucks, containers, and cargo within the facility.

- Secure Handling: Receive immediate alerts for door opening and shocks (improper handling).

- Cold Chain Assurance: Continuous temperature and humidity monitoring via dedicated cold chain solutions.

Equipment Health and Maintenance

- Proactive Maintenance: Use specialised devices for condition monitoring to track the performance of critical assets, such as pump motors.

- Maintenance Tracking: Simplify repairs and preventative work with housekeeping and maintenance tracking.

- Automated Intelligence: A Business Engine triggers custom rule-based alerts and notifications.

Technical Specification

- Integrated Solution: An end-to-end solution that includes Bluetooth Low Energy (BLE) beacons, sensors, gateways, cloud hosting, and RTLS software.

- Efficiency: The system is easy to deploy and runs on low power consumption.

Leveraging Digital Technology for Clear Visual Insights in Warehouse Operations

In a supply chain, Bluetooth RTLS solutions for warehousing inventory tracking, through the deployment of inventory tags, enable operations on the production floor to be depicted as multiple zones of moving inventory, creating a digital twin. Data needs to be gathered from various operations on the shop floor, and moving objects are effectively mapped in real-time. Without data, the visual representation is merely an empty concept. The question is how to build more of a twin and less of a hollow concept.

This boils down to several factors; some are organisational and operational, while others involve technology and the availability of know-how. The latter, in my view, is one of the biggest hurdles, but it is not independent of the technology or ecosystem of choice. At RipplesIPS, we believe in open-source technology and open API-based democratisation of access to machine-generated data, enabling the implementation of digital twins warehouse management, and transport management.

Digital Twin Warehouse Applications for Workflow Monitoring and Workplace Safety

For high precision tracking, Bluetooth AoA (Angle of Arrival) RTLS solutions for warehouses can also be extended to monitoring worker safety in logistics yards, construction sites, etc. Given an accuracy of 10 centimetres, it is possible to ascertain, using demand forecasting, the time spent by a group of people to trigger health safety when a worker crosses into a no-go zone. This will help in functions such as facilities management.

Bluetooth RTLS Solutions Driving Smarter Wireless Inventory Tracking

Improved sub-meter accuracy is achieved using Angle of Arrival (AoA) technology, which means that the cost structure of the Industry 4.0 solution will be appropriate and accessible to a larger, global audience. Many of the prevailing RTLS connectivity protocols incur huge expenses in the bill of materials by using outdated and proprietary radio HW and or transmission protocols.

Another important deployment aspect for consideration is the installation time and effort to configure your digital twins in transport management and warehousing. This has a direct impact on savings and can offer a large cost component in any industrial deployment of RTLS Inventory tracking in factories, warehouses, and construction industries. Our solutions around Bluetooth indoor positioning systems mesh network topology are truly self-organising and autonomous RTLS solutions for asset tracking systems in warehouses.

Algorithms running in each Bluetooth Low Energy radio decide how best to organise the network, its topology, and the use of the radio spectrum. This eliminates network planning, reduces installation time, and, most importantly, the deployment can be a simple part of daily routines by warehouse workers, saving a lot of time and effort in installation, implementation, cabling, inspection, and certification.

Call us to learn how to implement facilities management, Digital twin warehouse management, inventory tracking, transport logistics, cargo monitoring, and Bluetooth AoA RTLS solutions for an inventory tracking system in the warehouse. Patient Tracking System and Telecom tower tracking are some of the new application frameworks available with us.